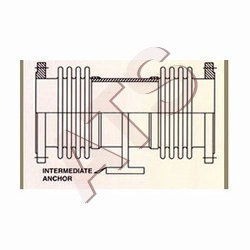

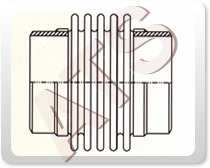

Double Bellows

Double Bellows Specification

- Application

- For Industrial & Workshop Use

- Feature

- Easy To Use

- Product Type

- Other

- Shape

- Round

- Surface

- Galvanized

- Size

- 5-50 Inch

Double Bellows Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Australia, North America, Eastern Europe, Central America, Middle East, South America, Asia, Africa

- Main Domestic Market

- All India

About Double Bellows

A double bellows refers to a mechanical device consisting of two flexible components connected together, typically made of airtight material such as rubber or synthetic fabric. The double bellows is designed to expand and contract, providing a means of accommodating movement or displacement while maintaining a seal or connection between two components. This device is commonly used in various industrial applications, including machinery, piping systems, and automotive systems.

FAQs:

Q: What is the purpose of a double bellows?

A: The primary purpose of a double bellows is to compensate for movement, misalignment, or vibration between two connected components while maintaining a seal or connection. It absorbs and accommodates expansion, contraction, or axial movement, ensuring the integrity and functionality of the system it is installed in.

Q: Where are double bellows used?

A: Double bellows find applications in a wide range of industries. They are commonly used in piping systems to absorb thermal expansion and contraction, reducing stress on the pipes. They are also employed in machinery to allow for movement and vibration isolation, preventing damage to connected components. Additionally, double bellows are utilized in automotive systems, such as exhaust systems and suspension systems, to absorb shocks and vibrations.

Q: How does a double bellows work?

A: A double bellows operates by utilizing the flexibility and elasticity of its two connected bellows components. When subjected to movement or displacement, the bellows expand or contract, allowing for changes in distance or position between the connected components. The bellows' accordion-like design enables it to compress or extend while maintaining a sealed connection.

Q: What materials are double bellows made of?

A: Double bellows are typically constructed from materials that offer flexibility, durability, and resistance to environmental conditions. Common materials include rubber, silicone, neoprene, and synthetic fabrics. The specific material used depends on the intended application and the requirements for factors such as temperature, pressure, chemical resistance, and wear resistance.

Q: Can double bellows be customized?

A: Yes, double bellows can be customized to meet specific requirements. Manufacturers often offer options for size, shape, material selection, and end connection types to ensure compatibility with different systems. Customization allows for optimal performance and proper integration into the specific application.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Expansion Bellows & Joints(S.S Metal) Category

Rubber Expansion

Minimum Order Quantity : 1 Piece

Shape : Round

Application : For Industrial & Workshop Use

Feature : Easy To Use

Product Type : Rubber Expansion, Other

Universal Bellow With Pipe

Minimum Order Quantity : 1 Piece

Shape : Round

Application : For Industrial & Workshop Use

Feature : Easy To Use

Product Type : Other

Size : 550 Inch

Axial Bellows With Pipe / Flanges

Minimum Order Quantity : 1 Piece

Shape : Oval

Application : For Industrial & Workshop Use

Feature : Easy To Use

Product Type : Other

Size : 550 Inch

Rectangular Metal Expansion Joints

Minimum Order Quantity : 1 Piece

Shape : Round

Application : For Industrial & Workshop Use

Feature : Easy To Use

Product Type : Expansion Joints, Other

Size : 550 Inch

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS