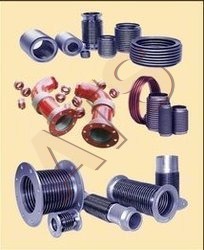

Universal Bellows

Product Details:

- Feature Easy To Use

- Application For Industrial & Workshop Use

- Product Type Other

- Material SS

- Shape Round

- Surface Galvanized

- Size 5-50 Inch

X

Universal Bellows Price And Quantity

- 100 Piece

Universal Bellows Product Specifications

- 5-50 Inch

- For Industrial & Workshop Use

- Silver

- SS

- Easy To Use

- Other

- Round

- Galvanized

Universal Bellows Trade Information

- Telegraphic Transfer (T/T) Cash in Advance (CID) Cheque Cash Advance (CA)

- 100 Piece Per Day

- 1 Week

- Western Europe Asia Australia North America South America Eastern Europe Middle East Central America Africa

- All India

Product Description

A universal bellows, also known as an expansion joint or compensator, is a flexible component used in piping systems to absorb thermal expansion, vibration, and misalignment while maintaining a leak-tight connection. It consists of one or more bellows units designed to accommodate axial, lateral, and angular movements. Universal bellows provide flexibility and stress relief, preventing damage to pipes and equipment and ensuring the integrity of the system.

FAQ:

Q: What is the purpose of a universal bellows?

A: The primary purpose of a universal bellows is to compensate for thermal expansion, vibration, and misalignment in piping systems. It absorbs the movement and stress caused by temperature changes, equipment vibrations, or structural settling, preventing damage to the piping and maintaining the integrity of the system.

Q: Where are universal bellows used?

A: Universal bellows find applications in a wide range of industries, including power generation, petrochemical, oil and gas, HVAC, and industrial processes. They are used in various system components such as pumps, turbines, compressors, heat exchangers, and ductwork, where the movement and stress caused by thermal expansion need to be accommodated.

Q: How does a universal bellows work?

A: A universal bellows consists of one or more convoluted bellows units that provide flexibility in multiple directions. When the connected piping undergoes axial, lateral, or angular movement due to thermal expansion, vibration, or misalignment, the bellows units flex and absorb the movement while maintaining a sealed connection. This helps to reduce stress on the system and prevent damage.

Q: What materials are universal bellows made of?

A: Universal bellows are typically constructed from materials that offer high flexibility, corrosion resistance, and temperature resistance. Common materials include stainless steel, Inconel, and other alloys suitable for the specific application requirements. The material selection depends on factors such as the operating temperature, pressure, corrosive environment, and structural considerations.

Enter Buying Requirement Details

Other Products in 'Expansion Bellows & Joints(S.S Metal) ' category

|

ATS HYDRAULIC ENGINEERS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS